Front Brake Pads for Nissan Silvia 2.0 DOHC Turbo QS 1991-1992 with copper grease sachet. Equivalent to DB1473

Product Code: PN2201-Nis_Sil

Price:

$23.95

RRP $55.00

56% OFF

In Stock

Share This Item:

| Specification | http://www.jnbk-brakes.com/catalogue/bikes/brake/1432/PN2201 |

| Product Type | Brake Pads |

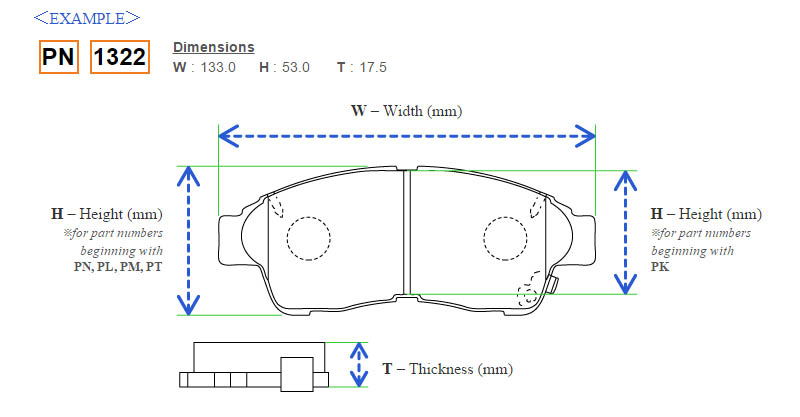

| Length | 137 mm |

| Packing Weight | 670 g |

| Width | 53 mm |

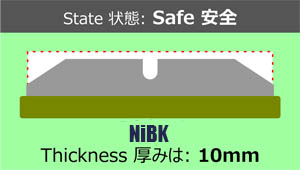

| Thickness | 16.8 mm |

| Kit | 4 Pcs |

| Compatible Makes | Nissan |

| Packing Width | 55 mm |

| Models | Silvia 2.0 DOHC Turbo QS |

| Original Part Number | 1Y1J-33-28Z D1060-88E90 D1060-AC20A D1061JA00A D106M-N2585 55810-80J50 55810-80J51 V9118-N021 D1060-88E86 D1060-88E87 D1060-88E91 D1060-9AJ0A D1060-EM10A D10601FE0A D10601KA1A D1060EM30A 55810-80J00 55810-80J01 AY040-NS090 AY040-NS101 AY040-NS102 AY040-NS106 AY040-NS119 41060-88E92 41060-88E94 41060-0V090 D1060-2Y991 D1060-85F90 D1060-88E85 D1060JN00A D1061-ZX60A 41060-AM892 41060-AU091 41060-ZG225 AY040-NS015 AY040-NS032 4106055F90 4106089EX2 AY040-NS055 AY040-NS062 AY040-NS818 AY040-NS822 AY040-NS078 AY040-NS082 41060-89E91 41060-89A90 41060-89E90 AY040-NS929 AY040NS138 41060-89EX1 NISSAN AY040-NS054 NISSAN 41060-8J090 41060-9J425 AY040-NS033 AY040-NS041 AY040-NS048 41060-2Y090 41060-2Y091 41060-2Y9X0 41060-40U90 41060-40U92 41060-2Y990 41060-40U93 41060-40U95 41060-4L090 41060-5L725 41060-5Y790 41060-73L91 41060-73L92 41060-73L93 41060-75T90 41060-88E90 41060-88E91 |

| Packing Depth | 140 mm |

| Build Years | 1991-1992 |

| Competitor Part Number | DB 1232 DB1187 GDB3390 FDB691 TN529M TN568M TN617M DB1485 FDB691 D1110 D1119 D1241 PN2504 |

| Packing Height | 70 mm |

| Fitting | Front |

| Package Type | BOX |

Be The First To Review This Product!

Help other Aurus Australia Pty Ltd users shop smarter by writing reviews for products you have purchased.